Self-sustained reservoir uses Westwater electro chlorinator

Logan Water were looking for an innovative approach to maintain water quality at the Round Mountain Reservoir at New Beith in Queensland. In collaboration with WestWater, the result was a state-of-the-art design, implementing the introduction of an electro-chlorination disinfection system, powered off the grid using solar panels in tandem with Tesla smart batteries for back-up on cloudy days.

The Hyprolyser system uses a brine solution to produce a 0.6% concentration of Sodium Hypochlorite on-site. The product is then stored and dosed into the water mains to maintain total chlorine levels in the water supply.

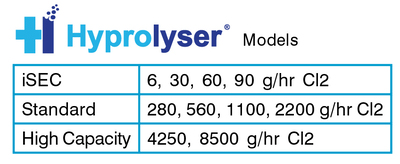

The electro-chlorination process includes two Hyprolyser 2200 electro chlorinators running in series to batch product and store in a 19,000 L HDPE product tank.

Dosing is completed by duty/standby digital dose pumps housed in one self-contained polypropylene dosing cabinet. There is also a bulk brine storage tank of 8000 L capacity, which sits below ground level under a false floor and is filled with salt via a monorail/hopper system capable of delivering salt in 1 ton bags.

What is electrolytic chlorination?

Hyprolyser electrochlorination systems offer a safer, cleaner and more environmentally friendly way to provide chlorine for a wide range of disinfection uses.

Using only salt, water and electricity to produce hypochlorite, each Hyprolyser model offers exactly the same quality of performance and benefits. Whether you are looking to disinfect a spa pool or provide enough chlorine to treat millions of litres of drinking water per day, there’s a Hyprolyser system available to perfectly fit your needs.

Why use electrochlorination?

Using salt as the raw material to generate your own supply of hypochlorite offers several advantages. Salt is a widely available commodity used in many commercial and industrial settings and is competitively priced for both small and large users. Compared to commercial chemicals, salt is very safe and easy to store, has an infinite shelf life and requires minimal packaging which can be easily recycled.

On-site generated Sodium Hypochlorite is 0.6% concentration and classified as non-hazardous unlike commercial Sodium Hypochlorite and Chlorine gas. The product does not deteriorate with time or temperature providing stability in the water treatment process.

Managing Aging Water Infrastructure: A Proactive Approach

Addressing aging infrastructure requires a fundamental change in mindset, moving beyond emergency...

Condensate and Cooling Water Monitoring and Aromatics Detection

optek's high quality materials withstand the toughest process conditions including aggressive...

ECD Turbidity Measurement Sensor

Designed with an innovative multi-beam optical sensor, highly intelligent electronics and...