A sustainable approach to increase wastewater recycling

Rising rural populations, drought and climate change are making water scarcity a problem in country townships — with more efficient handling of sewage system wastewater part of the solution.

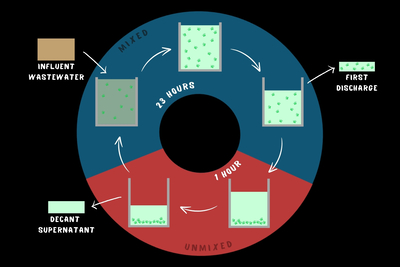

Pioneered by Flinders University environmental health experts, local councils in South Australia are operating sustainable energy-efficient sewage treatment operations with low-cost high-rate algal pond (HRAP) systems. Now new research led by the university is investigating improved effluent treatment and biosolids removal with ‘sequencing batch reactors’ — or low-cost ‘SBR-HRAP’ technology field trials — installed at SA Water’s Angaston wastewater treatment plant in the Barossa Valley.

The newer systems under development are designed to work better and faster without major capital expense — due to the latest research of new approaches for the bioprocessing inside them, said Professor Howard Fallowfield from the Flinders College of Science and Engineering. The SBR techniques under development involve a new kind of algae and improved removal of waste from the water, for better-quality non-potable water for use in parks, gardens, sporting fields and other purposes.

“Supported by SA Water and the ARC Biofilm Research and Innovation Centre at Flinders, we are trialling selective enrichment of algal–bacterial combinations to produce higher-quality treated effluent,” Fallowfield said.

“Using wastewater from the Angaston community, our six pilot-scale HRAP tanks will compare the performance of these improved processes against the original HRAP operations.”

Large high-rate algal pond systems, which have been treating wastewater at local council-owned facilities near Kingston-on-Murray and Peterborough in South Australia, use low-energy paddlewheels to move township and business organic waste along shallow channels where harmless green microalgae and bacteria remove pathogens and contaminants. PhD candidate Felipe Sabatté, who has used a native freshwater filamentous algal population to produce higher-quality clarified treated effluent, said the latest developments will be scaled up in the Angaston field trials.

“While high-rate algal ponds are an accepted method of wastewater treatment, particularly for regional and rural communities, they utilise microalgae which are difficult to remove from the treated wastewater, leading to unacceptably high suspended solids in the discharge,” Sabatté said.

“These larger filamentous algae offer the prospect of easier separation from the treated wastewater, significantly improving treated effluent quality.”

The outcome of this research provides a new operational strategy for wastewater HRAPs, particularly for the benefit of regional and rural communities challenged with water restrictions and to help meet UN SDG6 (clean water and sanitation) targets in the long run, he said.

This research was conducted by Flinders University-based Australian Research Council Training Centre for Biofilm Research and Innovation and funded by the Australian Government. The Training Centre is working with industry on a range of sustainable and environmentally friendly research solutions.

Also at the Angaston trial site, Training Centre PhD researcher Sam Butterworth is investigating how to use this new technology to develop dense algae–bacterial granules, which can be more readily removed from wastewater and potentially reduce phosphorus levels.

“Algae–bacterial granule formation is a positive way for biofilms to form dense, fast-settling biomass and improve treated wastewater quality,” Butterworth said.

“Using microalgae in high-rate algal ponds is increasingly seen as a better alternative to other wastewater treatment systems, such as activated sludge.” Indeed, traditional wastewater treatment methods can use more energy and water and be less sustainable due to higher greenhouse gas emissions.

An independent validation of the HRAP projects approved the treated wastewater to be used for non-food crop irrigation. For example, the Kingston-on-Murray ponds supply reuse water to irrigate a woodlot, and the ponds in Peterborough provide reuse water for a golf course and a sports field.

Phone: 08 8201 3911

ProMinent DULCOMETER diaLog C single-channel controller

The single-channel controller performs two-way control tasks and precisely controls two...

Rosemount 490A optical dissolved oxygen sensor

The sensor is a digital Modbus-enabled measurement device designed to improve operational...

Kaeser GBS series rotary screw blowers

This range of blowers offers high efficiency and low maintenance and is suitable for applications...