How Australia can increase its circularity rate

Hatch, an engineering, operational and development projects organisation (metals, energy and infrastructure), has said that Australia’s big mineral advantage is being held back by a linear system that sees raw materials exported for processing in China, and then imports the finished goods back, which often end up in landfill.

The company said the solution to this could lie in developing onshore processing plants and creating operational strategies that treat circularity as a core design requirement, not just an optional add-on.

Australia’s National Circular Economy Framework aims for a 10% reduction in per‑person material usage, a 30% increase in material productivity, and an 80% recovery of resources — which together could support reducing 14% of emissions and 26 million tonnes of waste each year.

Hatch’s Managing Director for Climate Change, Jan Kwak, said Australia has the capability to achieve the global average or even exceed it, adding “it just needs a robust framework”.

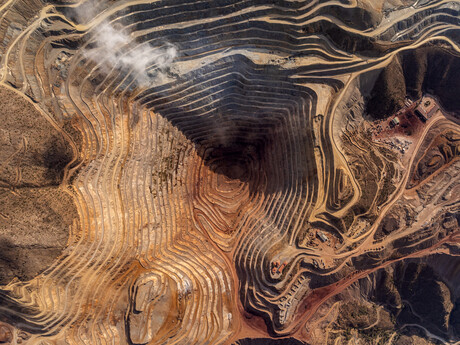

“Right now, we dig it up, ship it out and lose the circularity. Australia has enormous natural advantages in critical minerals; we have some of the world’s most valuable critical minerals, but we only capture the first step of the value chain. When processing happens offshore, recovery happens offshore too, and we lose control of the materials we’ll need again,” Kwak said.

“Australia is one of the world’s largest suppliers of minerals essential to clean energy, including iron ore, bauxite, copper, nickel and the precursors for lithium battery chemicals. But recent reporting shows most critical minerals are still refined in China, Indonesia and Malaysia before being re-imported as finished products.

Kwak said this reliance on foreign processing sharply limits Australia’s ability to build a functioning circular economy.

“If the refining and manufacturing happen somewhere else, then the reuse, remanufacturing and recycling happen somewhere else too. You simply can’t close a loop you don’t own.

“The country needs an operational roadmap for key sectors alongside enforcement measures so it’s able to meet the nation’s ambitious circularity targets.

“The government’s framework identifies the right sectors and levers, and now we need the implementation plan that will see circularity designed into every stage, with domestic processing and refining being key to that plan.

“That plan must signal to all industries to work towards a common goal — collaboration across sectors and influence spheres. With global tailings production now exceeding 9.9 billion tonnes per year, the unlocking of that value chain needs to happen now to fully leverage our capacity to exceed the 8% global circularity rate.

“As we think about resilience, we also need to think about the circularity opportunities we’re creating. Mines are shutting down due to declining ore grades and rising operational costs — this is the result when operators don’t capture the full value of the resource and regional potential.

“We need a new operating curve, and building domestic processing is key to that.”

Kwak said digital systems that track materials across their lifecycle, and implement modular designs that make infrastructure easier to repurpose are integral to circularity. Further, he said longer-term executive tenures are needed.

He said industries need strong methodologies that measure financial, social and environmental value generation, and added that Hatch is already applying circular thinking across its client engagements, and embedding it as a core focus of the company’s global strategy.

“Circularity is one of Hatch’s key market differences — it’s built into our planning, our client work and our future-facing innovation. It’s one of the ways we tackle some of the world’s toughest challenges and deliver sustainable positive change for tomorrow,” he said.

Scouts SA secures future of its recycling centres

Scouts SA has partnered with Container Deposit Scheme specialist Return-It to grow its Scout...

Mining waste provides strong boost to concrete construction

Flinders University researchers are turning mining waste into a tool for sustainable...

Partnership doubles medicinal blister pack recycling

Blooms The Chemist has recycled 20 million blister packs in the past 12 months, thanks to...