Could a melting discovery reshape plastics recycling?

Plastics do not decompose like natural materials, which has led to a vast build-up of unwanted plastic in the environment. Plastic waste can be eliminated by melting or burning, but this results in other problems such as toxic fumes and contribution to global warming. A method to melt different plastics together could be a solution.

The varying properties of different plastics poses a challenge when it comes to recycling. Separating and treating each type of plastic adds to the cost of recycling, which reduces the incentive to do so, despite the irreversible and detrimental biological cost of plastics in the environment. But what if different plastics could be recycled together?

Researchers Tingan Lin and Limin Bao — along with their team at Shinshu University, Japan — have examined the recyclability and sustainable development of thermoplastic materials. Thermoplastic materials soften when heated and harden when cooled, and can be cooled and heated several times without any change in their chemical or mechanical properties. Used in many industry and household applications, thermoplastics can be moulded into any shape.

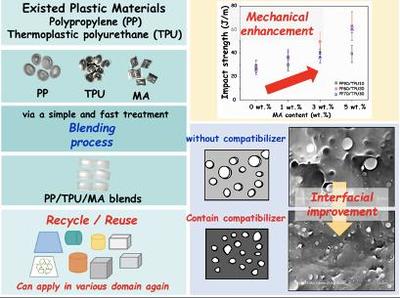

In the study, published in the Journal of Materials Research and Technology, the Shinshu University research team examined thermoplastic polyurethane and polypropylene — each plastic has a different melting point (at 145 and 165°C, respectively), so melting them together posed a challenge. To solve this issue, Lin and colleagues added a compatibiliser (polypropylene-grafted maleic anhydride) to act as a go-between, which enabled the plastics to be processed at the same time. The quality of the plastic was not undermined.

Using only a small amount of the compatibiliser, the researchers were able to efficiently produce thermoplastic blends using the melt extrusion and injection moulding processes.

The researchers hope their findings will allow unwanted plastic to be economically valued again and protect wildlife and the environment from further pollution. Professor Bao hopes to continue the study of thermal behaviours to see how they affect the reusability of thermoplastic-based materials.

Sustainability in 2026: what's next for Australian businesses?

No longer is it just about reporting; it's about using these frameworks to drive meaningful...

Net zero or 1.2 million homes: trade-off or win-win?

The housing accord's ambitious goal of building 1.2 million homes by June 2029 could impact...

How mandatory climate reporting is raising the bar for corporate leadership

The shift towards mandatory climate-related financial disclosures is transforming how...