Maximising copper recovery at mine sites

Researchers from Flinders University are testing a natural extraction technique for low-grade copper, known as supergene enrichment, for its potential to maximise recovery rates and extend mine life.

Professor Allan Pring, lead researcher on the project, said low-grade ore is often ignored because it is not seen as economically viable. “What tends to happen is a small amount of ore, about 10–15%, ends up in the tailings and waste piles and you don’t get all the metal out of the copper ore,” he said.

Professor Pring said his team, including Associate Professor Sarah Harmer, Dr Christopher Gibson and postdoctoral researchers, aims to optimise the amount of minerals recovered at mine sites and reduce waste. “If you could get that material out in a cost-effective way,” he said, “then you would not only maximise the amount of copper, but the extra copper could be worth millions and millions.”

“We are not setting out to improve the recovery of copper by a few percentage points,” added Associate Professor Harmer. “We are aiming to provide a new and innovative approach to the problem.”

Supergene enrichment is a natural process that occurs at copper deposits close to the surface, where the circulation of groundwater takes the primary sulfide minerals and redistributes it into copper metal. Associate Professor Harmer explained, “Mild oxidising reactions take place, causing the primary ore minerals, such as chalcopyrite, to be replaced by more copper-rich, less refractory minerals.

“These processes are driven by coupled dissolution-reprecipitation (CDR) reactions and in many CDR reactions, the reaction mechanism, rather than intensive properties such as pressure and temperature, control the nature of the products and the overall reaction process.”

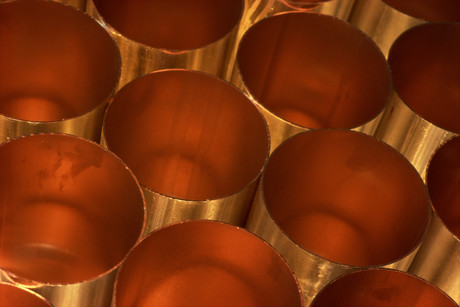

The research project will test the effectiveness of supergene enrichment at Flinders’ laboratories using special flow-through equipment developed at the university. The Australian Government has provided $485,000 in funding through the Australian Research Council’s Linkage Projects scheme, with an additional $300,000 being provided by BHP Billiton.

The success of the project would not only extend the life of jobs and infrastructure at remote mine sites, but reduce spending on the development of new mine sites. Professor Pring said he hopes to scale up to real-world tests within three years.

Concrete repair key to sustainability

This National Recycling Week, Building Chemical Supplies encourages the construction and...

Researchers to create 'affordable' jet fuel from plant waste

A research hub at The University of Queensland is taking a unique approach to converting plant...

Submissions wanted for tyre industry inquiry

The Australian tyre industry will be the focus of a new inquiry by the House of Representatives...