Industrial by-products clean up mercury pollution

Flinders University researcher Dr Justin Chalker has led the development of a new, cheap, non-toxic polymer that literally sucks mercury out of water and soil. The polymer is expected to have a big impact on both environmental and human health, as mercury exposure can damage the central nervous system and is particularly dangerous to pregnant women and children.

Sulfur-limonene polysulfide (SLP) is manufactured from sulfur — a by-product of the crude oil industry — and limonene, which is found in orange peel and is an unused waste material from the citrus industry. Dr Chalker explained, “We melt the sulfur and add limonene to it, and then can coat devices or make it into any shape we like.”

Both components are readily and cheaply available, Dr Chalker added, due to the global abundance of waste sulfur and limonene. This makes the polymer affordable for use in large-scale environmental clean-ups.

“More than 70 million tonnes of sulfur is produced each year by the petroleum industry, so there are literally mountains of it lying unused around the globe, while more than 70,000 tonne of limonene is produced each year by the citrus industry,” he said.

“So not only is this new polymer good for solving the problem of mercury pollution, but it also has the added environmental bonus of putting this waste material to good use while converting it into a form that is much easier to store so that once the material is ‘full’, it can easily be removed and replaced.”

By lining storage containers with SLP, Dr Chalker and his colleagues have successfully removed mercury from rivers, ponds and soil. The material can transform water from toxic to nearly drinkable, with concentrations of mercury reduced 1000-fold — from several parts per million down to several parts per billion.

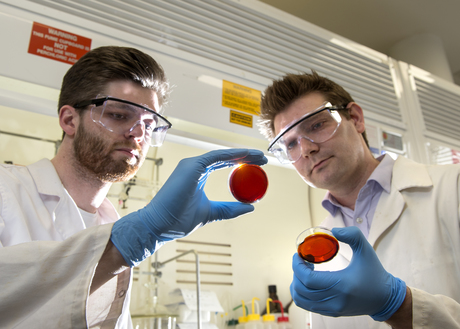

The dark red material, which looks like rubber, turns bright yellow when it absorbs mercury. Not only does this indicate that the SLP is saturated and “needs to be changed”, said Dr Chalker, but it also means it can be used as a mercury detector in areas where pollution is suspected.

After contact with SLP, the mercury remains permanently bound and can be stored safely without further environmental risk. Dr Chalker explained, “The mercury forms nano- and micro-particles that are embedded in the polymer and don’t get washed off even with flowing water.”

Dr Chalker’s research, which included contributions by Flinders University colleagues as well as The University of Tulsa, the Institute of Molecular Medicine at the University of Lisbon and the University of Cambridge, has been published in the journal Angewandte Chemie International Edition.

Council recycling service tackles difficult waste disposal

The service is specifically aimed at helping households dispose of items that cannot be placed in...

Greener method recovers critical metals from spent batteries

Researchers have developed a sustainable method to recover high-purity nickel, cobalt, manganese...

National solar panel recycling pilot program welcomed

ACOR has said the national pilot program for solar panel recycling is 'a timely and important...