Polymer additive to improve plastics recycling

Here’s a question for you: what percentage of the >70 million tonnes of plastic used annually for packaging — for example, a 2 L bottle or a takeaway food container — actually gets recycled and re-used in a similar way?

If you answered anything higher than 2%, we’ve got some bad news for you.

According to the Ellen MacArthur Foundation, nearly one third of plastic packing is leaked into the environment, while around 14% is used in incineration and/or energy recovery. A whopping 40%, meanwhile, winds up in landfills.

One of the main problems with plastics recycling is that polyethylene (PE) and polypropylene (PP), which account for two-thirds of the world’s plastics, have different chemical structures and thus cannot be repurposed together. Geoffrey Coates, from Cornell University, explained that if you “take a film of polyethylene and a film of polypropylene and you try to melt them together… it’s really easy to pull that film apart”.

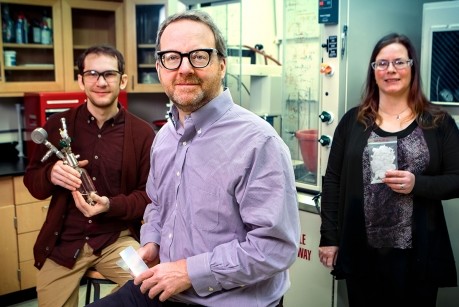

Now researchers at Coates’ lab have collaborated with a group from the University of Minnesota to develop a tetrablock (four-block) polymer. By adding a miniscule amount of this polymer to a mix of the two otherwise incompatible materials — with alternating polyethylene and polypropylene segments — the resultant material was found to have strength superior to diblock (two-block) polymers.

“People have done things like this before, but they’ll typically put 10% of a soft material, so you don’t get the nice plastic properties — you get something that’s not quite as good as the original material,” said Coates.

“What’s exciting about this is we can go to as low as 1% of our additive, and you get a plastic alloy that really has super great properties.”

The researchers’ study saw two strips of plastic welded together using different multiblock polymers as adhesives, then mechanically pulled apart. While the welds made with diblock polymers failed relatively quickly, the weld made of the group’s tetrablock additive held so well that the plastic strips broke instead.

“That’s the first sign that we’ve got a very good material to effectively glue together polyethylene and polypropylene,” said Coates, who published the study results in the journal Science.

Lead author James Eagan, a postdoctoral researcher in Coates’ group, said benefits of the tetrablock polymer are twofold. Not only does the polymer show promise for improving recycling, it could spawn a whole new class of mechanically tough polymer blends.

“If you could make a milk jug with 30% less material because it’s mechanically better, think of the sustainability of that,” he said. “You’re using less plastic, less oil, you have less stuff to recycle, you have a lighter product that uses less fossil fuel to move it.”

Tackling plastic waste in health care

With the support of APR Plastics, Recycle Wise has initiated a service previously missing in the...

From glass waste to energy-efficient bricks

Typical brick production produces harmful emissions and puts a strain on natural resources,...

How the perfect blend of tyres and plastic led to a sulfur-free oil

When tyres are broken down, the oil formed normally contains hazardous sulfur-containing...