Asphalt mixed with cigarette butts

RMIT University researchers have created asphalt mixed with cigarette butts — a product which has been found to handle heavy traffic as well as reduce thermal conductivity. Not only could their creation solve a huge waste problem, it would also be useful in reducing the urban heat island effect common in cities.

About 6 trillion cigarettes are produced every year, leading to more than 1.2 million tonnes of cigarette butt waste. These figures are expected to increase by more than 50% by 2025, mainly due to an increase in world population.

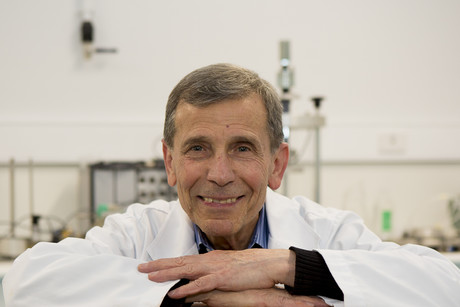

Most cigarette butts are discarded into the environment, where they take ages to break down while their toxic chemical load is released into creeks, rivers and the ocean. Dr Abbas Mohajerani (pictured), a senior lecturer in RMIT’s School of Engineering and lead researcher on the project, was keen to find a solution to this increasing problem.

“I have been trying for many years to find sustainable and practical methods for solving the problem of cigarette butt pollution,” he said.

“Cigarette filters are designed to trap hundreds of toxic chemicals, and the only ways to control these chemicals are either by effective encapsulation for the production of new lightweight aggregates or by incorporation in fired clay bricks.”

Dr Mohajerani and his team investigated the possibility of encapsulating cigarette butts with different classes of bitumen and paraffin wax and incorporating them into asphalt concrete for pavement construction, to lock in the chemicals and prevent any leaching from the concrete. “The encapsulated cigarettes butts were mixed with hot asphalt mix for making samples,” said Dr Mohajerani, whose work has been published in the journal Construction and Building Materials.

“Encapsulated cigarette butts developed in this research will be a new construction material which can be used in different applications and lightweight composite products.

“This research shows that you can create a new construction material while ridding the environment of a huge waste problem.”

Council recycling service tackles difficult waste disposal

The service is specifically aimed at helping households dispose of items that cannot be placed in...

Greener method recovers critical metals from spent batteries

Researchers have developed a sustainable method to recover high-purity nickel, cobalt, manganese...

National solar panel recycling pilot program welcomed

ACOR has said the national pilot program for solar panel recycling is 'a timely and important...