Sticky tape could help to develop thinner solar cells

A team led by the Australian National University (ANU) has used sticky tape to create atom-thick layers of phosphorus, called phosphorene, whose properties could open the door to ultrathin and ultralight solar cells and LEDs.

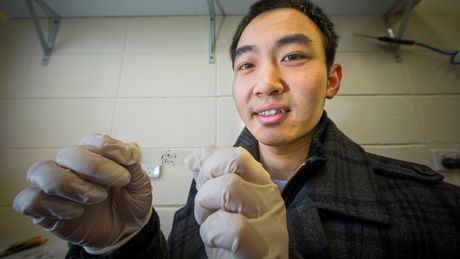

Writing in the journal Light: Science and Applications, the scientists explained how they created phosphorene by repeatedly used sticky tape to peel thinner and thinner layers of crystals from the black crystalline form of phosphorus. Phosphorene is a semiconductor, like silicon — which is the basis of current electronics technology — but much lighter and thinner.

Furthermore, the material has light-emission properties that vary widely with the thickness of the layers, which enables much more flexibility for manufacturing. According to lead researcher Dr Yuerui (Larry) Lu, “This property has never been reported before in any other material.

“By changing the number of layers we can tightly control the band gap, which determines the material’s properties, such as the colour of LED it would make,” continued Dr Lu.

“You can see quite clearly under the microscope the different colours of the sample, which tells you how many layers are there.”

Dr Lu’s team found the optical gap for monolayer phosphorene was 1.75 eV, corresponding to red light of a wavelength of 700 nm. As more layers were added, the optical gap decreased. For instance, for five layers, the optical gap value was 0.8 eV — an infrared wavelength of 1550 nm. For very thick layers, the value was around 0.3 eV — a mid-infrared wavelength of around 3.5 µm.

Additionally, Dr Lu said the behaviour of phosphorene in thin layers is superior to silicon. He explained, “Phosphorene’s surface states are minimised, unlike silicon, whose surface states are serious and prevent it being used in such a thin state.

“Because phosphorene is so thin and light, it creates possibilities for making lots of interesting devices, such as LEDs or solar cells.”

'Myrtle': Australia's new embodied carbon facility

Run by Australian cleantech company MCi Carbon, the facility will transform CO2 into...

Scientists make inroads into sustainable refrigeration

The research involved fine-tuning the compression-absorption cascade refrigeration cycle (CACRC)...

New initiative helps businesses make sustainable packaging choices

The AIP is collaborating with sustainability software company Empauer to offer a comprehensive...